Our Services

Broad Building Services is a specialist MEP building services BIM coordination and design company. With a team who understand your needs and our main target goal being, "make construction easy".

Building Services MEP Coordination

MEP Services coordination doesn’t start with a software such as Autodesk’s Revit, it starts with an understanding of the building, the Mechanical, Electrical and Public Health services and many other aspects of the project. The team start by reviewing all schematics, layouts, technical submissions, specifications, fire strategies, GA’s and many other relevant documents to ensure they can get an in depth look at what the project requires and help the process run smoothly.

After the Broad Building Services team have understood the specifics, they begin setting up a 3D model using our project template to ensure we keep all our work consistent and to the best of standards. The team will be split into sections depending upon the size of the project and how much 3D modelling is required.

All services are modelled so that they are running through the optimal routes minimising the need for any maintenance points and keeping costs to a minimal. At Broad Building Services you will be in safe hands knowing we focus on producing quality drawings and 3D models helping to minimise any issues on site.

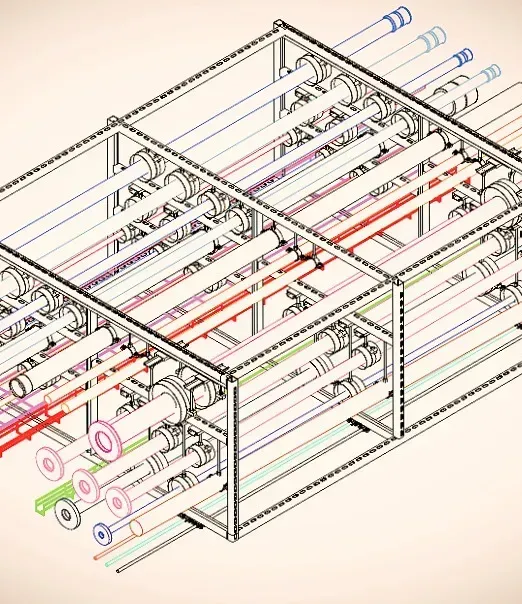

Plantrooms & Riser Modelling

The Broad Building Services team have worked on all types of Plantrooms and Risers. During this process the team have understood the need for maintenance access, installation access and the principles of all the services within the plantroom and/or risers. We work closely with the client at the beginning to understand what they require within the room and understand that sometimes the items/accessories such as valves may not have been procured so changes may occur after procurement. Our aim is to minimize issues on site by creating a 3D model that can be shown to the engineers and site team to understand how they can install.

When modelling the team consider all aspects of the services such as bracketry, expansion, vibration of pumps, drain points, air vents, replacement of heating/cooling coils and many other requirements. Our aim is to ensure we create the simplest version of the plantroom/riser in line with the CDM regulations, minimising costs, creating easy access, and aiding installation.

Prefabrication, Modularisation and Assembly

At Broad Building Services we create drawings and models to be used for manufacturing off site. The benefits are well known as they allow on-site installation time to be reduced. Our team have worked on projects that have required a high quantity of prefabrication from plantroom skids, MEP modules, riser modules and spools.

The team have been highly trained so that we have thought of the most intricate details, and we ensure to produce drawings, so they are easy to understand from the points of view of the manufacturing team. Our office structure has been created so that the team working on a prefab project are run like a production line helping to keep our work consistent and ensure that we are producing drawings at quite a fast pace.

At the initial stages of the project, we will discuss all requirements with the client and create all items in house such as clips, drop rods, Unistrut’s, expansion brackets, slide guides, etc. The team would work to create a few test prefab drawings to show the client what they can get and allow for them to comment on the drawings which in turn means our team create the clients’ ideal drawings tailored to their manufacturing site.

Clash Detection

One of the most important steps in Broad Building Services is the Clash Detection process. The Clash detection is done through the use of Navis Manage. This process helps to speed up projects by identifying clashes between services, architecture and structure during the coordination stage. The team can then inspect and report any clashes in a project model. There is extensive research showing that by the using a clash detection software it helps lower costs greatly by reducing the amount of on-site issues.

The team run a clash detection and send a report before the issue of drawings. This helps to give confidence to the client, knowing full well they are receiving a clash free model and/or drawings.

2D Drawing Production

At Broad Building Services we believe the main core aspect of any project is clear and accurate drawings. The team have produced countless drawings for large scale projects to smaller projects giving us an understanding of what standards and templates are best to be used. We comply with ISO 19650, BS 1192:2007 to ensure your project meets the UK Information Management mandate.

3D Animations & Visualisations

When you are presenting a concept or idea to a team, client, or any audience it may be difficult to do this with 2D drawings, reports or even a PowerPoint presentation. What you want is a 3D computer animation and visualisation.

At Broad Building Services we understand this and can cater to you by giving you some of the best options on the market. We like to stay ahead of the game by not just generating ideas on a computer or TV screen but also by reaching further, going beyond our competitors by creating a virtual reality representation.

Give yourself an edge in winning contracts by discussing your ideas with us and letting us help you with your concepts.